The global hog farming industry is moving towards intensification and standardization, and the demand for high-quality and efficient feed processing equipment is increasingly prominent. The pig feed pellet machine, as a core device tailored for pig feed production, plays a decisive role in improving feed digestibility, reducing wastage, and promoting healthy pig growth. Beyond pig feed production, the diversification of the farming industry also drives the development of specialized feed pellet machines for various animals and integrated feed production lines. Selecting the right equipment combination is the key to realizing cost-effective and sustainable farming operations.

Core Advantages and Working Principle of Pig Feed Pellet Machine

Pigs have different nutritional needs at various growth stages, from suckling piglets to fattening pigs, requiring feed with adjustable particle size, hardness, and nutrient density. The pig 1-45t/h feed pellet machine is customized to meet these dynamic requirements, with distinct advantages and scientific working principles.

- Key Advantages: It can produce pellets of different sizes (1.5-4mm) to match the feeding habits of pigs at different stages—fine particles for piglets to improve digestibility and harder, larger particles for fattening pigs to enhance satiety. The high-temperature extrusion process (around 70-80°C) can kill harmful bacteria and parasites, ensuring feed safety. Granular feed reduces wastage by up to 25% compared with powdery feed and is convenient for storage and transportation. Additionally, it enables precise mixing of additives such as probiotics and growth promoters, ensuring balanced nutrition for pigs.

- Working Principle: The crushed and mixed powdery raw materials (such as corn, soybean meal, bran, and fish meal) are conveyed to the pelleting chamber by a feeder. Under the extrusion of the pressure roller and die, the materials are compressed and formed through the die holes. The friction during extrusion generates heat, promoting starch gelatinization to make the pellets more firm and easy to digest. Finally, the cutter cuts the pellets into the required length, and the finished products are discharged after cooling and screening.

Specialized Feed Pellet Machines for Other Animal Species

In addition to pig feed pellet machines, different animal species have specific feed requirements, leading to the development of various specialized equipment:

- Poultry Feed Pellet Machine: Tailored for chickens, ducks, and geese, it produces small-sized pellets (2-4mm) with high hardness. The high-speed rotation and extrusion structure ensure uniform particle size and high pelleting rate, suitable for processing high-protein raw materials and effectively retaining nutritional components.

- Cattle Feed Pellet Machine: Designed for ruminants such as cattle and sheep, it has strong extrusion capacity to process high-fiber raw materials like straw and hay into granular feed (4-6mm). It improves the digestibility of roughage and can add molasses to enhance feed palatability.For details on cattle feed pelleting, please see:https://pelletmakingmachine.com/cattle-feed-pellet-machine/

- Aquatic Feed Pellet Machine: Specialized in producing floating, sinking, or slow-sinking feed for fish, shrimp, and crabs. It adopts low-temperature pelleting technology to avoid nutrient loss and uses special binders to ensure good water stability (remaining intact for 3-8 hours), reducing water pollution and feed wastage.

Integrated Feed Production Line Matching Pig Feed Pellet Machine

For large-scale hog farms and commercial feed factories, a single pig feed pellet machine cannot meet the demand for large-volume and continuous production. An integrated feed production line matching the pig feed pellet machine can realize automated operation and improve production efficiency.

A complete pig feed production line includes raw material cleaning equipment, crushing equipment, mixing equipment, pig feed pellet machine, cooling and screening equipment, and packaging equipment. The cleaning equipment removes impurities to ensure feed safety; the crushing equipment crushes bulk raw materials into fine particles; the mixing equipment uniformly mixes various raw materials and additives according to the formula; after pelleting, the cooling equipment cools high-temperature pellets to room temperature to prevent mildew; the screening equipment removes unqualified pellets; finally, the packaging equipment completes automatic weighing and packaging. Large-scale production lines can also be equipped with automated batching systems and dust removal equipment to further improve production precision and meet environmental protection standards.

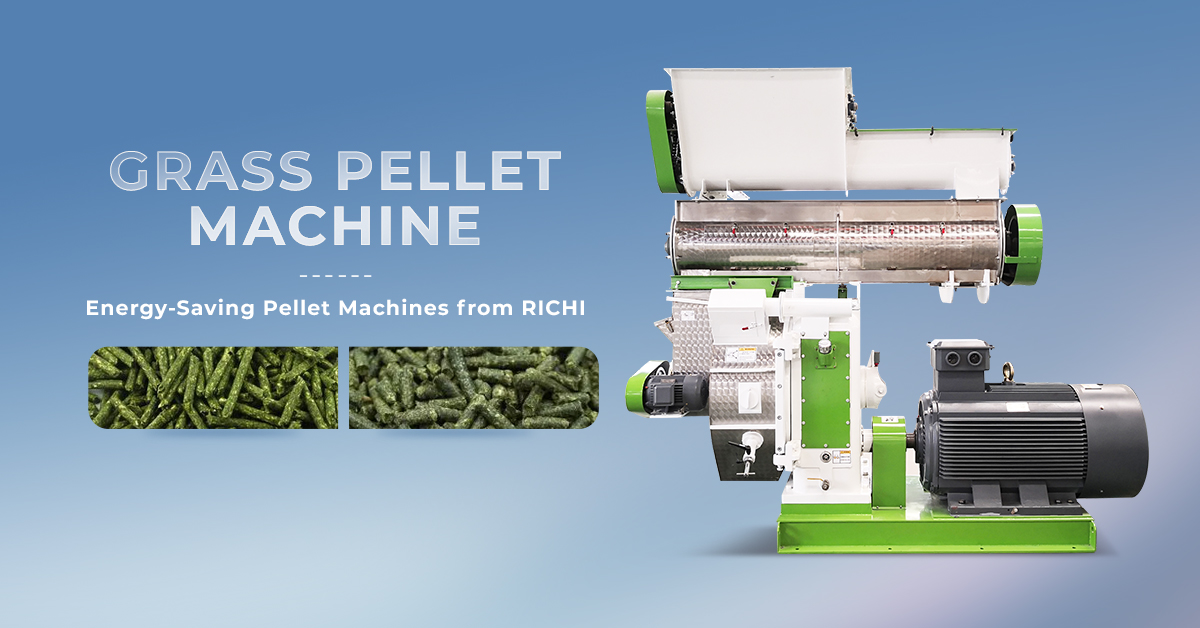

RICHI: Trusted Supplier of Pig Feed Processing Equipment

When selecting pig feed pellet machines and matching production lines, choosing a reliable brand is crucial. RICHI, a professional manufacturer of feed machinery with decades of experience, has won wide recognition from global users for its high-quality products and comprehensive services.

RICHI’s pig feed pellet machine adopts high-wear-resistant alloy dies and pressure rollers, ensuring long service life and stable performance. It supports customization of pellet size and production capacity according to user needs, from small-scale farm models (0.5-2 tons per hour) to large-scale industrial production lines (5 tons per hour or more). In addition, RICHI provides one-stop services including pre-sales formula consulting, production line design, on-site installation and commissioning, and after-sales maintenance, helping users solve equipment use problems efficiently. (go to website)

Key Considerations for Choosing Pig Feed Pellet Machine and Production Line

To select the most suitable pig feed pellet machine and production line, the following factors should be considered:

- Production Scale: Small-scale hog farms can choose a single pig feed pellet machine with a capacity of 0.5-2 tons per hour. Large-scale feed factories should select integrated production lines with a capacity of 5 tons per hour or more to meet mass production needs.

- Pig Growth Stages: Select equipment with adjustable die specifications to produce pellets of different sizes and hardness, matching the nutritional needs of pigs at different growth stages (piglets, growing pigs, fattening pigs, and sows).

- Automation Level: Evaluate the automation level based on labor resources and management capabilities. Fully automated production lines reduce manual intervention but have higher investment; semi-automated equipment is more suitable for small-scale operations with limited budgets.

- Equipment Quality and After-Sales Service: Prioritize equipment with high-quality core components to reduce later maintenance costs. Choose manufacturers that provide timely after-sales services, including technical support and spare parts supply, to ensure uninterrupted production.

Conclusion: Choose the Right Pig Feed Pellet Machine for Efficient Hog Farming

The pig feed pellet machine is an indispensable core equipment for modern intensive hog farming. Matching it with specialized feed pelletizers for other animals and integrated feed production lines can significantly improve feed quality and farming efficiency.

By considering production scale, pig growth stages, automation level and other factors, and cooperating with a trusted brand like RICHI, you can obtain high-performance equipment and professional solutions. This will help reduce farming costs, improve pig growth performance and survival rate, and achieve sustainable and profitable development in the competitive hog farming industry.