1. Introduction: The Importance of Goat Feed in Modern Farming

Goat farming plays a significant role in global agriculture, providing meat, milk, fiber, and hides. Proper nutrition is essential to maintain health, productivity, and reproductive performance in goats. A goat feed making machine is critical for producing uniform, nutrient-rich feed pellets that meet the dietary requirements of goats at different growth stages.

Traditional feeding methods, such as grazing or using raw grains and agricultural by-products, often result in uneven growth and reduced productivity. Mechanized feed pellet production ensures goats receive balanced nutrition, optimizes feed conversion, minimizes wastage, and supports sustainable and profitable farming operations.

2. Historical and Cultural Context of Goat Feeding

Goats have been domesticated for thousands of years, with origins in the Middle East and Central Asia. Historically, goats were raised primarily on natural pastures, supplemented with grains, hay, or crop residues. While these methods provided basic nutrition, they could not support large-scale or commercial goat farming efficiently.

The advent of the goat feed pellet making machine marks a major advancement in livestock husbandry. Pelletized feed enables precise nutrition delivery, reduces selective feeding, and improves overall flock health. In countries with extensive goat farming, such as India, China, Australia, and Kenya, mechanized feed production has become essential for optimizing efficiency while combining modern technology with traditional grazing practices.

3. Components and Function of a Goat Feed Pellet Making Machine

A standard goat feed pellet making machine system comprises several key components designed for efficient and high-quality feed production:

Raw Material Grinder / Hammer Mill: Reduces grains, alfalfa, soybean meal, and other ingredients into fine powder for uniform mixing.

Mixer: Ensures thorough blending of proteins, vitamins, minerals, and other additives.

Pellet Mill / Extruder: Compresses the mixed feed into uniform pellets suitable for goats of different ages and sizes.

Dryer: Reduces moisture content to prevent spoilage and prolong shelf life.

Cooling System: Stabilizes pellets and prevents breakage during storage and transport.

Packaging Unit: Prepares feed for storage, distribution, and commercial sale.

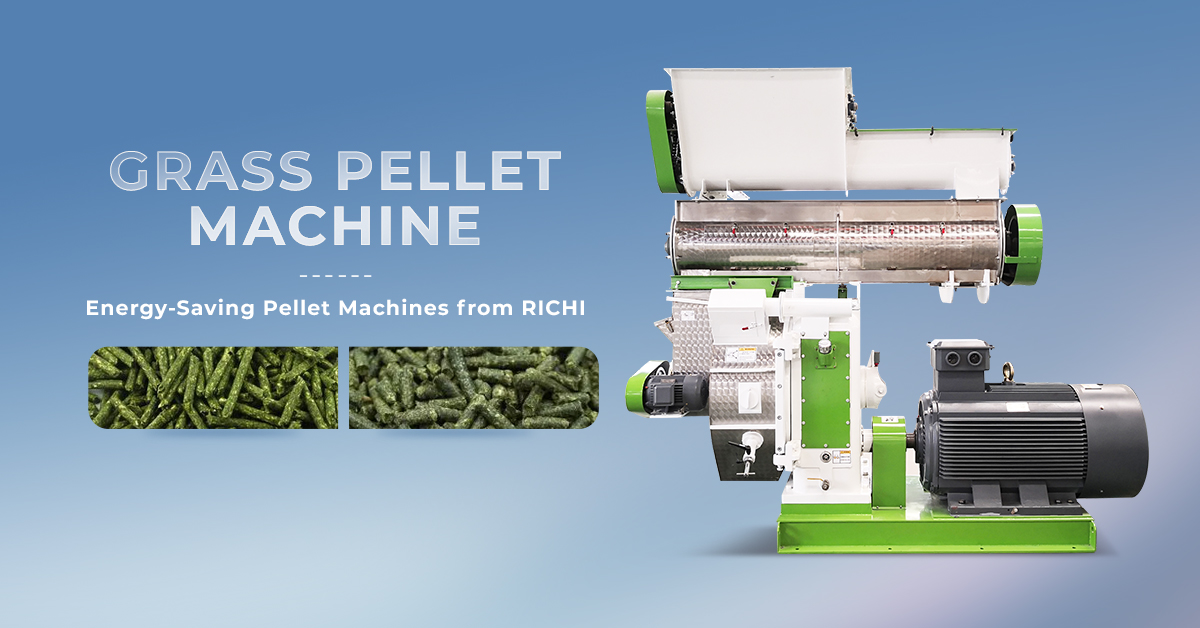

Modern goat feed pellet making machines, including those provided by RICHI, often feature adjustable pellet sizes, automated operation, and energy-efficient designs. These machines are suitable for small farms as well as large commercial goat operations. https://richipelletizer.com/livestock-feed-pellet-mill-for-sale/

4. Advantages of Using a Goat Feed Pellet Making Machine

Investing in a goat feed pellet making machine offers multiple advantages for goat farmers:

Balanced Nutrition: Ensures consistent delivery of proteins, vitamins, minerals, and other essential nutrients.

Improved Growth and Health: Optimized feed promotes weight gain, milk production, and reproductive efficiency.

Reduced Feed Waste: Uniform pellets minimize selective feeding and wastage.

Scalability: Machines can support small herds or large commercial operations.

These advantages contribute to healthier goats, higher productivity, and improved farm profitability, making mechanized feed production a key investment for modern goat farming.

5. Technological and Environmental Considerations

Producing high-quality goat feed pellets requires precise control of moisture content, temperature, and pellet density. Improperly processed feed may crumble, lose nutrients, or reduce digestibility.

Modern goat feed pellet making machines, including solutions from RICHI, incorporate advanced extrusion, drying, and cooling technologies with automated monitoring systems. This ensures consistent feed quality, maintains nutrient integrity, and optimizes energy efficiency.

Environmentally, pellet production reduces feed waste, allows the use of agricultural by-products, and supports sustainable livestock farming practices. Efficient feed production minimizes energy consumption and limits environmental impact.

6. Economic and Market Significance

Feed accounts for a major portion of goat farming expenses. Using a goat feed pellet making machine allows farms to produce feed on-site, reducing dependence on purchased feed, lowering costs, and improving operational efficiency.

The global demand for goat products—including meat, milk, and fiber—continues to rise. Mechanized feed pellet production enables farmers to produce high-quality, nutritionally balanced feed, improving flock growth, reproductive performance, and market competitiveness. Pelletized feed also supports healthier animals, reducing disease risk and enhancing profitability. Website

7. Choosing the Right Goat Feed Pellet Making Machine

Selecting the appropriate goat feed pellet making machine requires careful consideration:

Capacity: Small-scale machines may produce 0.5–2 tons per hour, while industrial machines can produce 5–20 tons per hour.

Feed Type: Pellets suitable for kids, growers, or adult goats.

Automation Level: Advanced systems reduce labor, improve consistency, and ensure precise pellet formation.

Supplier Reliability: Reputable manufacturers such as RICHI Machinery provide technical support, spare parts, and long-term maintenance services.

Choosing the right machine ensures reliable feed production, consistent quality, and sustainable goat farming operations.

8. Cultural and Nutritional Importance

Goat products are an essential source of protein, vitamins, and minerals for human diets in many regions worldwide. A goat feed pellet making machine ensures goats receive balanced nutrition, supporting optimal growth, reproductive performance, and overall health.

Culturally, goat farming supports rural livelihoods, creates employment, and strengthens local economies. Mechanized pellet feed production enhances these benefits by improving efficiency, reducing labor intensity, and allowing farmers to integrate modern technology while preserving traditional husbandry practices.

9. Conclusion: Investing in Sustainable Goat Feeding

A goat feed pellet making machine represents a strategic investment in modern, efficient, and sustainable goat farming. By producing nutrient-rich, uniform feed pellets, farmers can improve flock health, minimize feed waste, and increase overall productivity.With reliable equipment from suppliers such as RICHI, goat farms can scale operations, maintain consistent feed quality, and meet growing global demand for meat, milk, and fiber. Modern pelletized feed production combines technological innovation, economic efficiency, and environmental responsibility, shaping the future of sustainable goat farming. Animal Feed Pellet Plant in Iran